Zhejiang Steriger Sports Medicine Technology Co., Ltd. is located in Yiwu, China. We have obtained the "National High-tech Enterprise" honor in developing and manufacturing sports supports, medical braces, daily supports, and sports protection socks.

Steriger's production plant covers an area of 20 acres and has over 300 employees. We have more than 25,000 square meters of production space and about 30,000 cubic meters of automated warehouse. Up to now, we have over 60 Germany-made STOLL flat knitting machines, over 200 different types of circular knitting machines, and different terry sock machines. We are also equipped with self-developed semi-automatic high-frequency pressing and stamping machines. At the same time, we have implemented SAP, MES, WMS, and other systems to realize the digital management of the whole process, from raw material supply to product delivery.

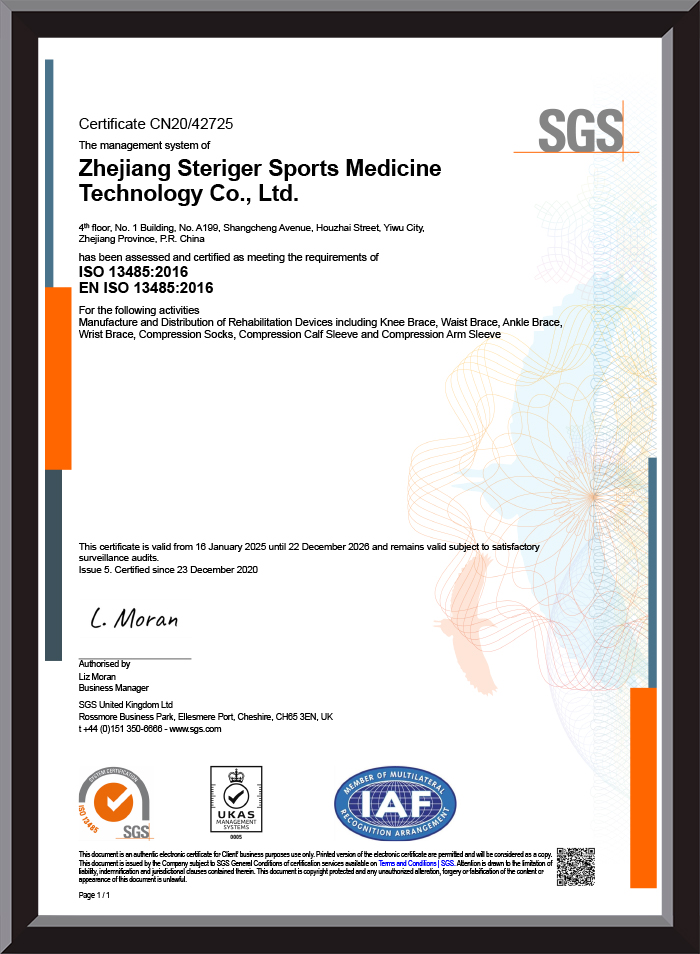

Steriger has established a mature quality management system. We have successfully obtained a FDA Medical Device Record Certificate, a CE Certificate, an ISO 13485 Medical Device Quality Management System Certificate, an ISO 9001 Quality Management System Certificate, etc. We have established an industry-leading supports and braces testing laboratory, equipped with advanced testing equipment to ensure that product parameters meet rigorous technical and quality standards.

Steriger has established a professional and efficient R&D team. We can provide one-stop solutions, from design to mass production. Meanwhile, we have established a joint R&D center with Donghua University. With DHU's unparalleled academic advantages in textile technology and material science, we are committed to promoting product innovation and technological development in the supports and braces industry.

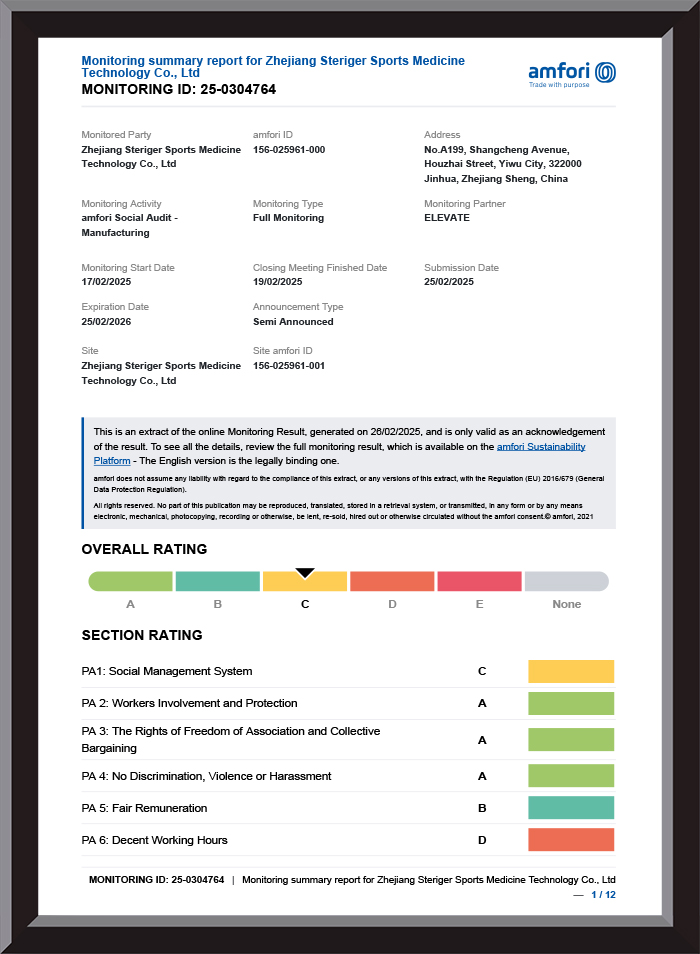

Steriger has always valued and fulfilled social responsibilities by holding social welfare and employee development activities. With the implementation of a solar energy generation project and other energy-saving projects, we aim to build an environmentally friendly factory. By now, we have obtained ISO 14001, IS0 45001, BSCI, CSR, SMETA 4P, Higg Fem, and other social responsibility-related certifications.

English

English

Español

Español Deutsch

Deutsch عربى

عربى Français

Français